Filing the Nodes

The rod starts off as a single 12 ft. length of Tonkin bamboo. This length is cut into two 6 ft halves, which will become the butt and the tip of the rod. The first process is to begin filing down the nodes in the bamboo.

Splitting the Bamboo

Next, each 6 ft section is split in half lengthwise, each half to thirds, each third to halves, then finally each piece is halved again. This yields approximately twenty-four 1/4 inch wide pieces from each of the 6 ft sections.

Working the Nodes

The nodes on what was the inside face of each strip are planed away and the outside is filed again.

After being filed, heat is applied to the nodes to make them pliable. A machine vise is used to compress the nodes flat and straighten bends in the strips.

The nodes are staggered for their final placement in the rod and each strip is cut to the approximate desired length. These lengths vary depending on the overall length of the rod being made.

Rough Planing

After the basic lengths are established, the two faces of each piece that were revealed during splitting are planed down. A special form is used to plane each strip accurately and uniformly. The resulting shape of the cross section is a triangle with all three sides at 60 degree angles. Six of these triangular strips will be bound together to form the final hexagonal shape of the rod.

Binding and Heating

The rough planed pieces are bound together using a four-string binding machine then heated in a custom made oven for 15-18 minutes at 350°F. This heating removes excess moisture from the bamboo making it stronger and more durable.

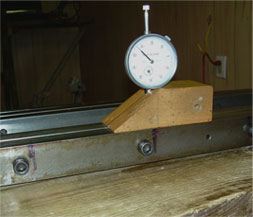

Final Planing

Another form is used to plane the desired taper into each piece of the rod. The taper of the rod determines the “action” experienced while casting. The form is precisely set for the desired taper using a depth gauge.

Once the form is set, the strips are planed to the final taper of the rod.

Gluing and Heating

The six pieces forming the two sections (the butt and the tip) are glued and bound together using the binding machine.

Glued sections are left in the heating chamber until cured.

Once completely cured, the glue and binding thread along with the natural enamel is scrapped off the assembled rod sections or “blanks”.

Mounting the Hardware

With the excess glue removed and surfaces smoothed, hardware such as the ferrules, guides, and reel seat can be mounted on the blank. Once the guides are placed they are wrapped with bands of silk thread which give the rod an attractive bit of color.

Varnishing and Curing

Finally, the rod is protected and sealed by slowly dipping it four times in polyurethane spar varnish. The newly varnished rod is hung to cure for a couple of weeks.

Once cured, the rod is complete.